Many corrugated dispensing displays utilize gravity to effectively drop the product into place once one product is removed. Essentially, the products are stacked in a display that is mounted high on an end cap. The product is displayed at a reasonable height so the consumer can take it and another product will drop down into the window for the next consumer. Using a display in this fashion allows stock to be held on the floor, behind graphics, yet allowing one focused dispensing area. This arrangement is often used and well tested. However, the question we ask is; why leave the entire area below the display empty? Wouldn’t it be a great idea to double the amount of product, and graphics, so that the product will optimize its selling potential?

Using an up-feed display, the space below the vending area can be utilized effectively. Imagine a spring-loaded display that gently lifts the product into place so the consumer can purchase it. An up-feed display can be used in conjunction with a gravity feed display, allowing for double exposure and sales potential.

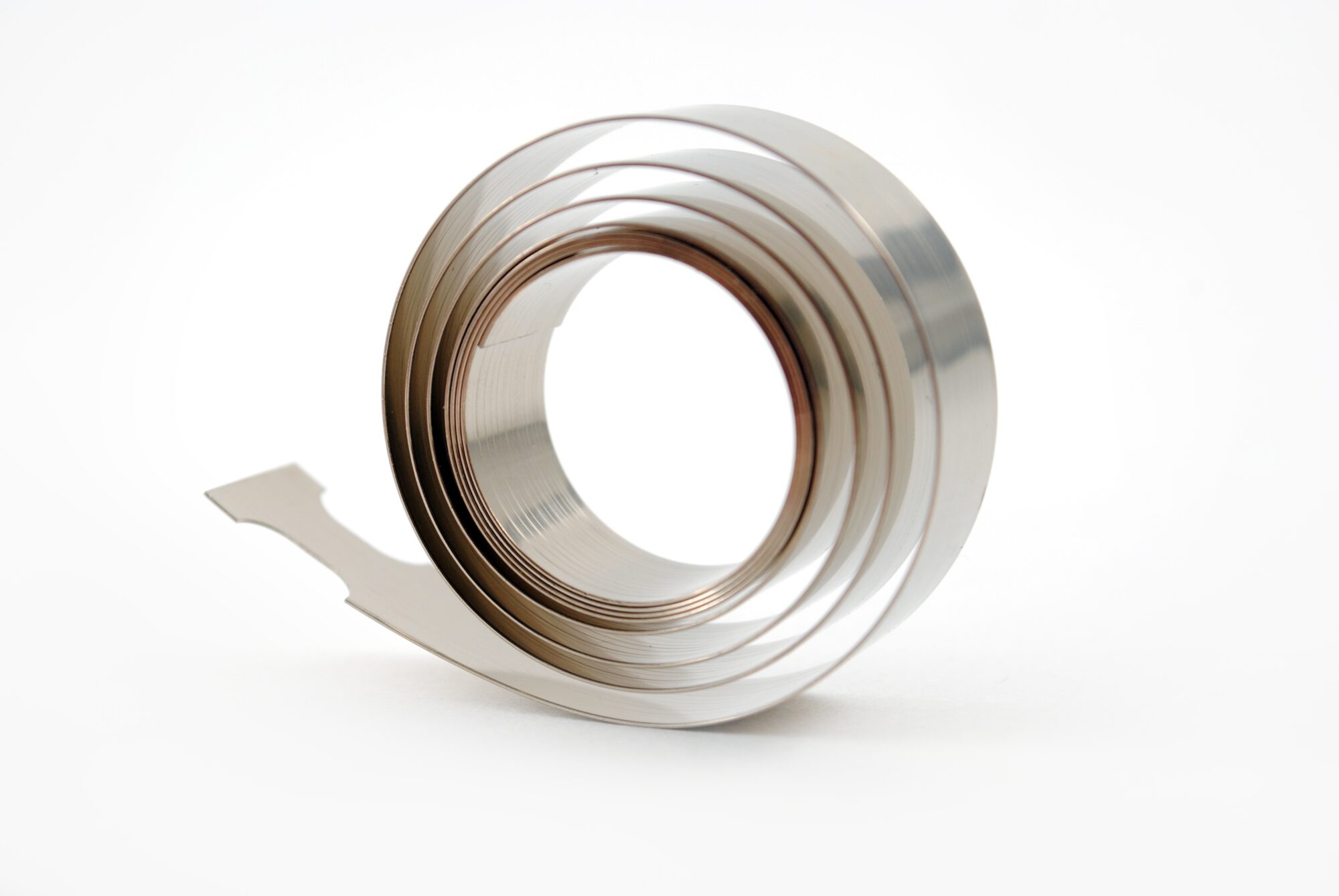

The design starts with a corrugated piece that sits below the product and pushes it up. This piece is often called the “elevator” since it lifts the product. The “elevator” is not flat but it has sides to keep it steady while moving up in the display. It is common than that two Variable Force “V” Springs will rest under the elevator. These springs are attached at the top of the unit through a slot in the corrugate.

The design starts with a corrugated piece that sits below the product and pushes it up. This piece is often called the “elevator” since it lifts the product. The “elevator” is not flat but it has sides to keep it steady while moving up in the display. It is common than that two Variable Force “V” Springs will rest under the elevator. These springs are attached at the top of the unit through a slot in the corrugate.

Additional benefits can be gained by reinventing the corrugated display:

- Product is always displayed at the ideal height for customer convenience

- A more efficient design with increased usable product volume

- Increases promotional surface for larger and more powerful graphics

Experienced Vulcan Spring engineers can assist in finding the proper force “V” spring along with the best end detail for your application. As always, it is recommended that you contact us early in the design stage.