At its core, spring mounting is about ensuring optimal performance and longevity for Constant Force Springs. The mounting process isn’t restricted to just placing the spring onto a spool or shaft. Every design project comes with its own set of complexities and requirements. To make the most informed decision, one must delve deep into the specific needs and constraints of the project at hand. Factors including available space, desired force output, and expected operational lifespan are pivotal.

Conforce® Springs, or Constant Force Springs, are versatile and crucial components in various applications, known for their ability to provide a consistent force over an extension. A vital aspect of their effectiveness lies in their mounting and arrangements.

Different methods and arrangements exist, each offering its unique benefits and challenges. By exploring these techniques, we can shed light on the nuances of spring manufacturing and offer guidance on achieving the best outcomes.

Conforce® Spring Mounting

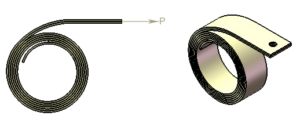

A constant force spring, regardless of the overall mounting arrangement, may be mounted by engaging either the inside or the outside of the coil. Spool mounting and cavity mounting, respectively, are the typical methods.

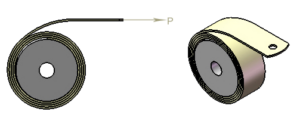

Spool Mounting

Spool mounting is one of the most discussed techniques in Conforce® spring manufacturing. Contrary to common misconceptions, mounting a constant force spring isn’t restricted to spools.

Advantages — The primary benefit of spool mounting lies in its capacity to reduce friction, ensuring a smoother and more repeatable operation. The choice of material for the spool and shaft interface is crucial and should be centered around minimizing friction throughout the spring’s lifecycle.

Disadvantages — Spool mounting does come with its challenges. The spool’s diameter should exceed the spring’s inside diameter by about 15%–20%. This is because of the 10% tolerance associated with a spring’s inner diameter. When released, the spring should sit snugly on the spool, ensuring it retracts efficiently.

Misconceptions arise when people assume that the spring must be attached to the spool, which isn’t the case.

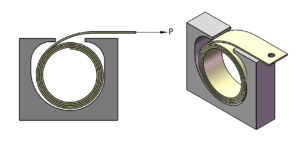

Cavity Mounting

Placing a constant force spring in a cavity offers an alternative mounting technique. The method generates more friction but comes with the benefit of fewer components.

Advantages — The standout benefit of cavity mounting is its ease of assembly.

Disadvantages — Designing the perfect cavity is crucial. A poor design can lead to increased friction and a compromised spring operation.

Conforce® Spring Arrangements

Understanding the nuances of various mounting methods is key in ensuring the optimal performance, effectiveness, and ease of assembly for constant force springs.

Single Coil

Advantages — Simplicity in design and ease of implementation.

Disadvantages — Limited force output compared to combined arrangements.

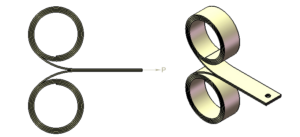

Back-to-Back and Tandem

Advantages — These arrangements offer increased force output. Back-to-back provides stability with two springs unwinding in opposite directions. Tandem, while not offering the same stability, is preferred when space constraints make back-to-back mounting infeasible.

Disadvantages — Adequate spacing is essential for both arrangements. Assembly is also more challenging than with a single coil.

Back-to-Back:

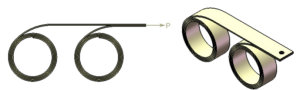

Tandem:

Laminar

Advantages — Provides a compact solution with high force output in limited space.

Disadvantages — Best suited for short extensions as the springs might bind if extended too far.

The Power of Precision

Here at Vulcan Spring, our commitment is to deliver excellence in spring manufacturing. Whether you’re exploring spool mounting, cavity solutions, or any other method, we’re equipped to provide custom solutions that go beyond the spring.

Explore the endless possibilities of constant force springs and partnership with Vulcan Spring. We’re dedicated to ensuring optimal mounting for effectiveness and longevity. Our team is always ready to assist if you have questions or need more information about custom springs and mounting solutions. Connect with us anytime!