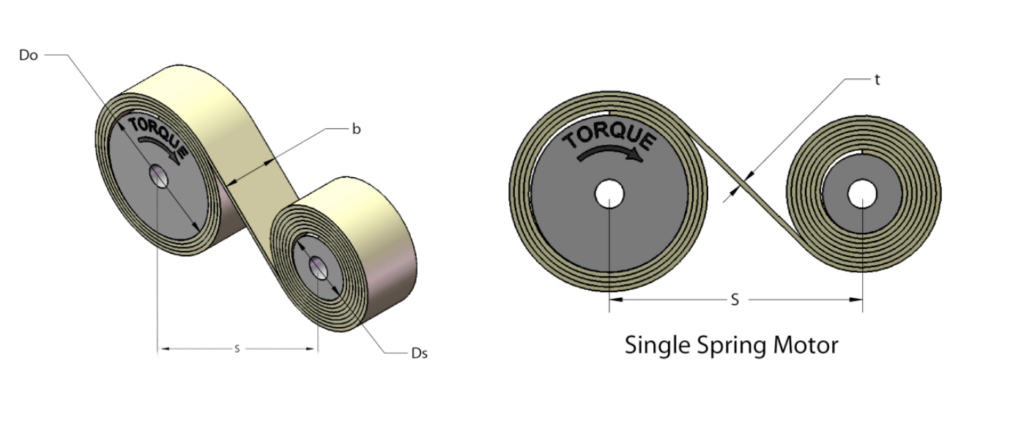

A constant torque spring is a specially stressed constant force spring traveling between two spools. The spring is stored on a storage spool and reverse-wound onto an output spool. When released, torque is obtained from the output spool as the spring returns to its natural curvature on the storage spool.

The spring doesn’t need to be attached to the storage spool. The spring can be housed in a cavity, eliminating the need for a storage spool altogether. However, friction is then introduced and can change the torque requirements.

The torque produced by a constant torque spring will increase slightly over many turns. Constant torque, or even negative torque, is also possible. Negative gradients of up to 50% can be achieved in certain applications.

When considering the use of a constant torque spring, it’s highly recommended that you speak with an engineer and work through various design parameters. However, it’s possible to make some initial design calculations by following the eight steps described here. Download our Design Guide for additional details.

1. Select the Material

Most of the springs we produce are made from Type 301 stainless steel. This material is readily available and predictable. A Vulcan Spring engineer can assist in choosing a standard size to expedite the process. We also use high carbon steel, Inconel, and Elgiloy in various designs as required.

2. Estimate the Life

This is one of the most important considerations since the life of a constant torque spring is very predictable. It’s important to be realistic since estimating a high life cycle requirement can lead to a larger, more expensive design. Of course, underestimating life cycles can lead to premature failure. The Design Guide is separated into life cycle charts.

Commonly chosen life cycle amounts are from 4,000 life cycles to about 25,000 life cycles. Designs can be made to higher life cycles, but increased tolerances of diameter and force should be considered. This is mainly due to the low-stress level of such a spring and the slight variances in the material.

3. Establish the Torque

There are a wide range of factors to account for in your design when establishing the correct torque for your spring. Torque is simply a measurable twisting force that tends to cause rotation.

How is Spring Torque Calculated?

The torque of a torque spring or torsion spring is calculated by dividing the spring rate by the number of degrees of deflection that your spring will travel. The torque of the spring should be equal to the requirement of the application. Standard tolerance for the force of constant force spring is ± 10%.

4. Determine the Space

When reviewing charts in the Design Guide, it will become obvious that several thickness and width combinations can be used to create the same torque. The inside diameter (I.D.) of the spring is dependent on the thickness, life cycle and force required. The outside diameter (O.D.) is dependent on the above with overall length as an additional consideration. The standard tolerance for the I.D. and O.D. is ± 10%.

5. Calculate the Total Length

The total length of the constant torque spring should account for the actual number of turns of the spring on the output spool plus at least enough material to keep 1 1/2 turns on the spring when fully rotated. The formula for determining length is as follows: L=π N (Do +Nt) +10 Do

The above formula accounts for:

- Diameter buildup

- Number of revolutions required (N)

- Thickness of material (t)

- Output spool diameter (Do)

6. Select the End Detail

This end detail will connect the spring to the output spool. We have many standard end details available.We have a full Tool and Die department capable of creating many designs required by our customers.

7. Calculate the Minimum Spool Spacing

The distance between spool centers (dimension “S”) must be greater than the radius of the spring when fully wound on the storage spool, plus the radius of the spring when fully wound on the output spool.

8. Finalize the Design

Once the above criteria have been reviewed and the constant torque spring can be located or extrapolated from the design charts, a spring part number can be introduced. Our system for assigning part numbers to designs is simple. The part number identifies the following:

- The letter from the selected life table

- The thickness of the spring in mils

- The letter code of the width of the spring (taken from the charts)

- The overall length in inches

NOTE: Part numbers don’t include the end detail, pickup length, or any other special requirements.

As an example, the spring with part number V5D46 specifies Type 301 Stainless Steel, 4,000 life cycles (V), .005” thick (5), 1/4” wide (D), and 46” long. From our design charts, we also know the torque will be .52 inch-pounds when mounted on a .58” diameter storage spool and a 1.01” output spool.

Please note that we don’t rely on the part numbers for exact specifications. They only distinguish the part from the others that we produce. Individual specifications, even if they vary slightly from the standard charts, are captured within the description. This explanation is a general overview of the part numbers that may be generated for you.

Custom Springs for All Types of Applications

Interested in constant torque springs? We’re a a preferred global supplier of custom springs. We’re recognized for our superior capabilities, from fully custom designs to mass production. Using innovative engineering, machinery, and tooling, we deliver effective spring solutions for even the most challenging applications. Check out our inventory!

If you have any questions about capabilities or would like to discuss your unique needs with one of our experts, don’t hesitate to contact us.