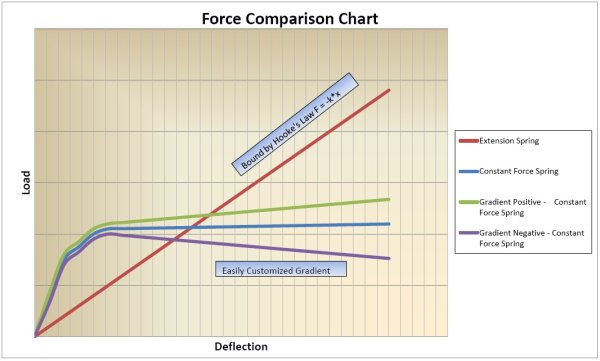

What differentiates the constant force spring from the conventional extension and compression (round wire) spring? Hooke’s Law states that the extension of a spring is directly proportional to the load applied to it. Therefore, the further an extension spring is extended, the greater the force.

The graph below shows that constant force springs are not bound by Hooke’s Law, and they provide a constant force over the length of travel. We can categorize the springs that we produce as:

- Constant Force Springs – Springs that offer high force output with small space requirements, provide long linear reach with minimal force buildup and store power indefinitely when extended.

- Gradient Positive or V Springs – Springs that demand a stronger force as the spring is extended and are at their strongest when fully extended.

- Gradient Negative Springs – Springs that decrease or weaken in force when extended, opposite of a gradient positive spring.

How Are Constant Force Springs Made?

On extremely long constant force spring designs, there’s a mechanical advantage to the changing diameters, and the force increases as the spring extends. However, this amount of increase is minimal and mostly constant compared to extension springs and can be negated if necessary.

The life cycle of a constant force spring is set by the diameter of a certain thickness of the steel.

Understand Different Types of Constant Force Springs

A constant force spring can be utilized to apply a linear extension force. At Vulcan Spring, our trademark name for this type of spring is Conforce®. When discussing a linear extension, we specify the force in lbs. (Kg, N, etc.) of pull force. This spring is used to push or pull one or more objects, or to counterbalance an object throughout its travel length.

An alternate version of this spring is called a constant torque spring. Our trademark name for this type of spring is Contorque®. When discussing the torque spring, we work in inch-lbs. (NM etc.) of torque. This spring is wound onto an output spool providing rotational torque and is commonly used to wind up cable, provide torque in toys, and other applications requiring rotational torque.

By designing a constant force spring into a product, the engineer can save space and provide for the correct amount of force required for the design.

Gradient Positive (V Springs) and Gradient Negative Springs

In addition to the types of constant force springs above, Vulcan is also able to change the force of springs over the travel length to match customer requirements. These springs are referred to as gradient positive (V springs) and gradient negative springs.

Gradient Positive Springs or V Springs

There are applications that demand a stronger force as the spring is extended. A very popular example of this is for pusher trays in stores. When a product is removed from the shelf, the next one comes forward, keeping the product upfront so the customer can see and buy it. In this situation, there are many products lined up in a row and the spring pushes them forward. As a product is added, the weight required to push increases. Vulcan will customize the spring’s force gradient to adequately increase as the spring is extended. When there are a few products remaining on the shelf, the force of the spring is at its minimum.

A gradient positive spring is also known as a variable force “V” spring and is relatively easy to differentiate from a constant force spring.

Gradient Negative Springs

Certain applications may require the opposite action as discussed above. Sometimes the requirement is for the spring to weaken as it is extended. For these applications, Vulcan can produce a gradient negative spring. One example of this is used with our Constant Torque Configuration. We use the constant torque spring in a Pullbox used to hang signs. When the store wants to change the sign, they pull the sign down so an employee can access it.

If the sign were to stay down when extended, the spring would be too weak to counterbalance the sign back up at the ceiling. This would allow the sign to sag or drift downward. Since this is usually not acceptable, Vulcan has engineered a gradient negative spring. This spring is designed to provide the maximum force when the cable is retracted and holding the sign at the ceiling. As the employee pulls the sign down the force of the spring decreases allowing the sign to float and stay wherever it is placed. For any counterbalancing application, a gradient negative spring may be required.

Gradient negative and constant force springs have the same physical appearance.

Your Complete Source for Custom Springs

We hope this gave you a deeper understanding of the versatility of constant force springs, and the other custom spring designs we offer here at Vulcan Spring like the V springs, gradient negative springs, and constant torque springs.

Contact us with any questions you have about our extensive custom spring solutions. Our experienced team can design and manufacture the right springs for all types of commercial, industrial, and manufacturing applications. We partner with engineers, contract manufacturers, and designers to produce springs for medical equipment, retail displays, and residential and commercial windows. If you already know what types of springs you need, head over to our online store.