Sometimes a point of purchase pusher tray needs to move products that are stacked three or four items high, such as baby food or pet food, and here may be six or seven of these stacks being pushed in one row on a display shelf. Other times, a single column of glass bottles, potato chip bags, or candy bars needs to be delicately pushed forward. A new technique used to accomplish this function integrates a pusher tray, a variable force spring, and a rotary damper.

For many years, the pusher tray has used the variable force spring. Vulcan pioneered this type of spring and designed many variations in use all over the globe that essentially push a product forward or upward as they’re removed from the front or top of the display. Today we’ll discuss the newest innovation to this system—the rotary damper mechanism.

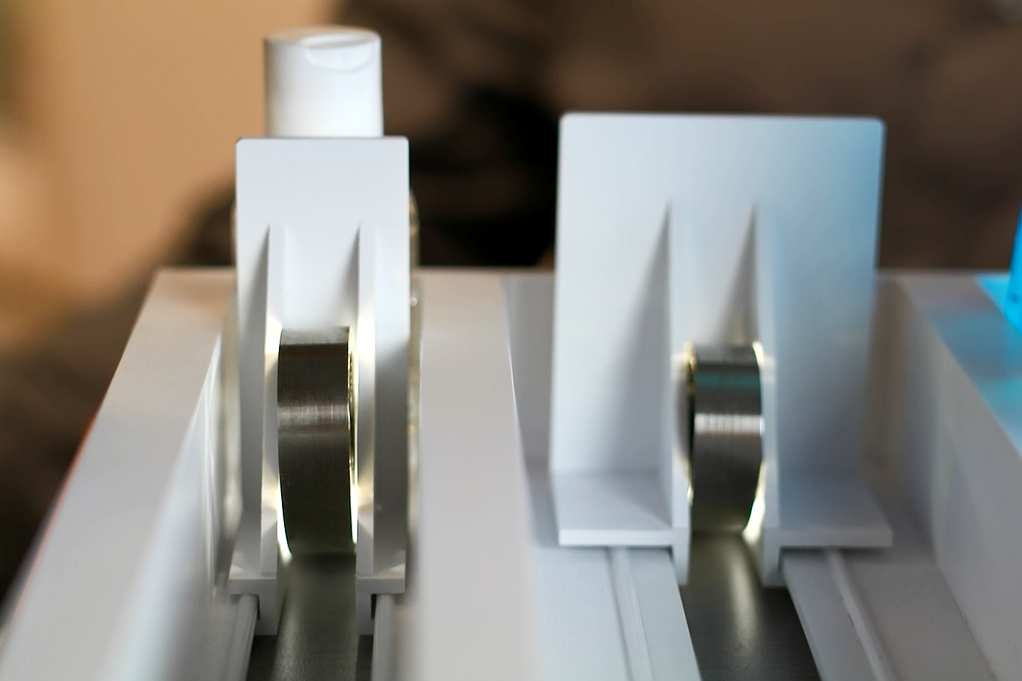

Vulcan has experience designing springs to work with rotary dampers. Traditionally, this spring and damper combination can be found in automotive, consumer and industrial applications. But the rotary damper is now finding its way into point of purchase trays where it provides smooth acceleration for moving products forward.

Are you looking to place an order for a custom rotary damper for your next point of purchase display? Contact Vulcan today to start working with one of our engineers on your custom design.

How a Rotary Damper Works

A rotary damper enables a mechanism to operate with a smooth, controlled motion. The damper is filled with a viscous fluid, such as silicone, which passes through rotating vanes, providing damping resistance. The resistance force is determined by the viscosity of the fluid and the design of the rotating vanes within the device. This is all accomplished in one small unit that can be incorporated into a larger mechanism. Rotary damper devices are typically found in automotive cup holders, DVD players and copy machines.

Designing a display with both a variable force spring and a rotary damper can be a difficult balance of resistance and force. Dampers can provide resistance in a clockwise rotation, counter clockwise rotation or both.

Special care must be taken to design a spring with the correct amount of force. The damper in these displays will slow the speed of the pusher moving forward. The damper will not reduce the force exerted but will reduce the speed at which the full force is applied.

As an example, an oversized spring with dampening will slowly advance a bag of potato chips to the front of the display. However, the force of the spring is still present and the pusher will slowly continue to advance. The chips can be slowly crushed as the bags are forced together until the resistance of the crushed bags matches the force of the spring, but by then it could be too late for the poor chips! Properly engineering a pusher feed mechanism that pushes products forward without damaging the merchandise requires precise engineering to balance variable spring size and force with a proper rotary damper, saving the chips from being crushed.

Designers should be aware that rotary dampers change resistance force based on their environment. In cold temperature applications, the damper will move slower than in room temperature and hot environments. Therefore, care must be taken to best replicate the final location of the display throughout the design process. For instance, if the display is being used in a cooler, the damper should be kept cold just up until the test is made. If possible, test the entire display in a cooler. This would result in the best design of the variable force spring and damper system.

Benefits of a Damper

When implementing a rotary damper into point of purchase displays, trays can more delicately push products forward in a controlled manner that’s custom-fit for the force required to move the item on display. When products are moved at a specified force and speed, they resist damage from the pusher trays and from being pushed forward improperly, compromising the design and functionality of the display.

Rotary dampers in point of purchase displays create smoother pusher tray mechanisms, minimize merchandise damage, and create a more organized and impactful display front.

Vulcan Spring and Your Next Point of Purchase Display

When considering a rotary damper for your point of purchase pusher, it is best to contact Vulcan early in your design process. A Vulcan Spring engineer can assist in testing and evaluating the entire working system to recommend a spring to purchase. Reach out to us today, we’re excited to work with you!