Post SHOT Show® 2022

“We’re All In”, was the motto for the nation’s largest professional event for industry products, manufacturers, sport shooting, and hunting held in Las Vegas, Nevada. Vulcan Spring & Mfg. had the pleasure of attending and exhibiting at SHOT Show®, meeting many prestigious firearm suppliers, and discussing firearm components/accessories.

At Vulcan Spring we recognize that loading and reloading a magazine should be fast, smooth, and efficient. When it comes to military and defense scenarios, as well as game hunting, every second counts. The performance of these magazine springs must be precise to properly feed a new round every time the firearm cycles.

Challenges with Current Compression Spring

The most common spring used for this application are compression springs. Compression springs are reliable and effective, but Vulcan Spring has proven that there is a magic bullet (pun fully intended), or rather a more compatible magazine spring to use. These would be our constant force springs or Conforce® springs. Vulcan is ready to defend the theory that constant force springs, when installed under the follower of the magazine, allow for easier loading and reloading.

Compression springs produce higher resistance from an applied force per each increment of compression distance. With each additional round that is added to the magazine, the ability to load and reload becomes increasingly difficult. We’ve all been there – when manually loading an extended Glock mag, at about the 12th round you need to pull out the loading assist device.

Benefits of Constant Force Springs

Constant force springs, contrary to compression springs, see very little increase in force during their working extension, thus nearly eliminating an ever-increasing resistance per round that is loaded. Vulcan Spring is able to dial in the precise force that minimizes resistance, while still allowing for enough pull force to ensure proper cycling of the firearm.

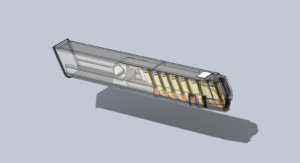

During SHOT Show® Vulcan showcased this custom spring solution that is tailored for a more enjoyable and effective firearm experience. No matter the magazine type or design, Vulcan will consider the magazine’s loading and space envelope requirements to allow for the best spring to be designed and manufactured for your application.

During SHOT Show® Vulcan showcased this custom spring solution that is tailored for a more enjoyable and effective firearm experience. No matter the magazine type or design, Vulcan will consider the magazine’s loading and space envelope requirements to allow for the best spring to be designed and manufactured for your application.

Outside of the magazine, there are many other types of springs for firearm applications that Vulcan is able to manufacture. These other custom springs include but are not limited to: detent, buffer, safety selector, forward assist, and buffer retain springs. Specifically, in terms of torsion springs, which are commonplace in firearm applications, Vulcan can produce Hammer, Trigger, and dust-cover springs to list just a few examples.

Although Vulcan Spring does not produce replacement firearm application springs at low volume, we aim to (no pun intended) consult with Project Managers and Engineers to prototype and produce custom springs with high-volume production potential.

Keep a lookout for our upcoming Firearms Case Study & Video with the focus on force testing compression and constant force springs.

Have questions? Call us at (215) 721-1721, we’ll answer the phone!