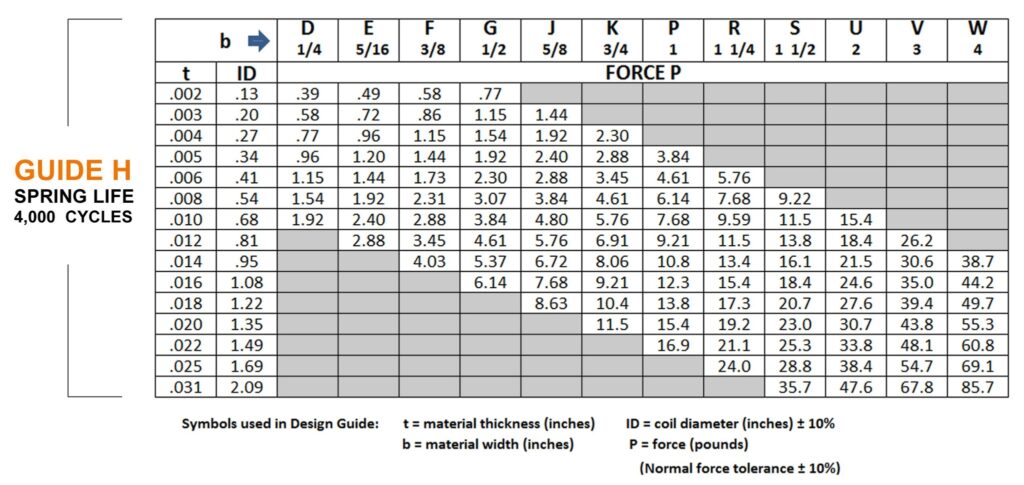

Why are there blank squares in the Design Guide?

You can see that there are two areas (shown in gray) in the chart where the force data is purposely left empty. We will discuss some of the reasoning behind the empty spaces.

The top right area of the chart represents thin material thickness and wide width specifications. This combination is left blank because these spring designs tend to have a large cross-sectional curvature. This is an unstable design that will not follow the theory of “width is directly proportional to the force”. You can see that when working in the stable range of spring design the force along a certain thickness row is directly proportional to the width. However, multiple tests have shown that the thin, wide designs will not follow the same theory. Thin, wide springs are not efficient because the potential energy is trapped as energy required to produce the cross-curve.

The bottom left area of the chart represents thick material with a narrow width. Sometimes slitting thick steel to narrow widths is the issue in this area. Other times the spring design can be unstable due to the material falling off the coil diameter because the width is narrow as compared to the thickness. Constant Force Springs in this area of the chart may also have a tendency to buckle or curl at the start of the return stroke.

It is best to stay in the stable area of the Design Guide charts for custom spring designs. If space does not allow for this, thorough testing is advised in order to approve a design from outside of the stable area.

It is best to stay in the stable area of the Design Guide charts for custom spring designs. If space does not allow for this, thorough testing is advised in order to approve a design from outside of the stable area.

If you need further assistance with designing your constant force spring, contact us today!

Interested in Constant Force Springs? Purchase springs online